DCS1000-ZS(Filling material: Granule, Weigh on top)

DCS1000-ZS(Filling material: Granule, Weigh on top)

Introduction

DCS1000-ZS is mainly composed of gravity filler (Variable diameter valve control), frame, weighing platform, hanging bag device, bag clamping device, lifting platform, conveyor, electrical control system, pneumatic control system, etc. When the packaging system works, in addition to the manually place bag, the packaging process is automatically completed by the PLC program control, and the procedures of bag clamping, blanking, metering, loose bag, conveying, etc. are completed in turn; The packaging system has the characteristics of accurate counting, simple operation, low noise, less dust, compact structure, convenient installation, safety and reliability, and safe interlocking between the workstations.

Characteristics

| Characteristics | ||

| Filler | Gravity filler (Variable diameter valve control) | |

| Count | Weigh as hanging | |

| Control system | Functions such as automatic drop correction, error alarm and fault self-diagnosis, Equipped with a communication interface, easy to connect, network, can be the packaging process at all times monitored and networked management. | |

| Scope of material:Poor fluidity of powders, granular materials. | ||

| Scope of application:Chemical, pharmaceutical, feed, fertilizer, mineral powder, electric power, coal, metallurgy, cement, biological engineering, etc | ||

| Paramete | ||

| Capacity | 20-40bag/h | |

| Accuracy | ≤±0.2% | |

| Size | 500-2000Kg/bag | |

| Power souce | Customized | |

| Pressure air | 0.6-0.8MPa. 5-10 m3/h | |

| Blowing rat | 1000 -4000m3/h | |

| Environment:Temp -10℃-50℃. Humidity<80% | ||

| Accessories | ||

| Convey option | 1. No 2. Chain conveyor 3. Chain roller conveyo 4. Trolley…. | |

| Protection | 1. Explosion-proof 2. No explosion-proof | |

| Dust elimination | 1. Dust elimination 2. No | |

| Material | 1. Steel 2. stainless steel | |

| Shake | 1. Up and down(standard) 2. bottom shake | |

Packaging operation process

1. Weigh sensor parameters.

| Specification | SB-1 | Minimum static load | 0Kg |

| Accuracy class | C3 | Minimum calibration division value | 0.14Kg |

| Maximum capacity | 1t | Sensitivity | 2.000mv/v |

| Safe limit load | 150%RC | Zero outpu | <1%RC |

| Insulation resistance | ≥5000MΩ | Input impedance | 381±4Ω |

| Excitation voltage | 5-15V | Output imped | 350±1Ω |

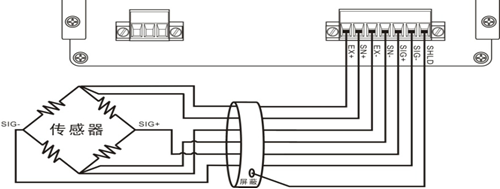

2. The controller needs an external resistance strain bridge sensor, and the sensor is connected to the instrument as shown in the figure below. When using a four-wire sensor, the SN+ and EX+ of the instrument must be short-circuited, and SN- and EX- must be short-circuited.