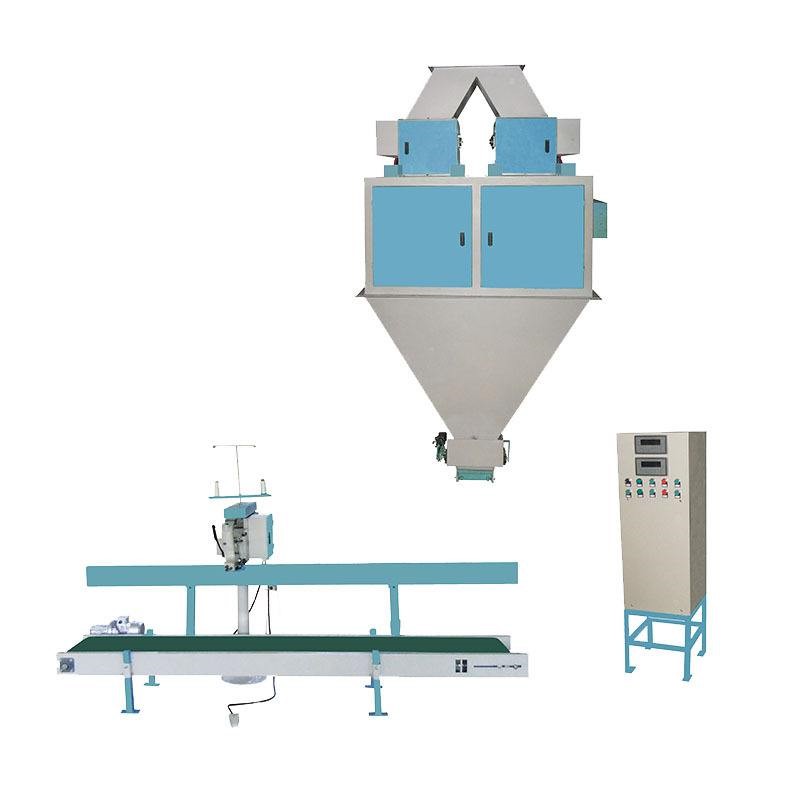

DCS50-C2(Filling material: Granule, Two weighing hopper)

DCS50-C2(Filling material: Granule, Two weighing hopper)

Introduction

DCS50-C2 is mainly composed of Gravity filler/Auger filler, frame, weighing platform, hanging bag device, clamping device, lifting platform, conveyor, electrical control system, pneumatic control system, etc. When the packaging system working, in addition to the manually place bag into position, the other packaging process is automatically completed by the PLC program control, and the procedures of bag clamping, blanking, metering, loose bag, conveying, etc. will perform in turn; The packaging system has the characteristics of accurate counting, easy operation, low noise, less dust, compact design, easy installation, safety and reliability, and safety interlocking between the workstations.

Characteristics

| Characteristics | ||

| Filler | Gravity filler/Auger filler | |

| Count | Double net weight counting | |

| Control system | Functions such as automatic drop correction, error alarm and fault self-diagnosis, Equipped with a communication interface, easy to connect, network, the packaging process at all times is monitored and networked management. | |

| Scope of material:Powders, granular materials. | ||

| Scope of application:Chemical, pharmaceutical, feed, fertilizer, mineral powder, electric power, coal, metallurgy, cement, biological engineering, etc | ||

| Paramete | ||

| Capacity | 300-700bag/h | |

| Accuracy | ≤±0.2% | |

| Size | 6-60Kg/bag | |

| Power souce | Customized | |

| Pressure air | 0.6-0.8MPa, 5-10 m3/h | |

| Blowing rat | 600 -2200m3/h | |

| Environment:Temp -10℃-50℃, Humidity<80% | ||

| Accessories | ||

| Place bag | 1, Manually 3, Automaticly | |

| Protection | 1, Explosion-proof 2, No explosion-proof | |

| Dust elimination | 1, Dust elimination 2, None | |

| Material | 1, Steel 2, stainless steel | |

| Palletizzing | Manual Palletizzing, High-low Palletizzing,Robot Palletizzing | |

| Sew | Automatic 2.Manual | |

Main components and functions

1 Filling mechanism: good accuracy of material filling control and close the filling automaticly; control the accuracy of material filling through the rotation angle of the valve plate, that is, the size of the flow section, and close the filling valve when the weight is good.

2 Weighing platform: It is equipped with a Toledo bellows load cell, which is used to measure the weight of the material and put the material into the packaging bag.

3 Platform bracket: used to support equipment and easy to maintain equipment.

4 Electical control box: centralized exhaust, box body sealed, cylinder and solenoid valve control.

5 The weighing system is electronic scale measurement, the weighing control display instrument is digital display, and the full-panel digital adjustment and parameter setting are used to make the operation process very easy. Correction, out-of-tolerance alarm and fault self-diagnosis and other functions. The instrument is equipped with a communication interface, which is convenient for online and networking, and can monitor and manage the packaging machine in office.