DCS50-FL(Filling material: Powder)

DCS50-FL(Filling material: Powder)

Introduction

DCS50-FL is mainly composed of filler, frame, weighing platform, hanging bag device, bag clamping device, lifting platform, conveyor, electrical control system, pneumatic control system, etc. When the packaging system works, in addition to the manually place bag, the packaging process is automatically completed by the PLC program control, and the procedures of bag clamping, blanking, metering, loose bag, conveying, etc. are completed in turn; The packaging system has the characteristics of accurate counting, simple operation, low noise, less dust, compact structure, convenient installation, safety and reliability, and safe interlocking between the workstations.

Characteristics

| Characteristics | ||

| Filler | Screw filler | |

| Count | Counting as hanging | |

| Control system | Functions such as automatic drop correction, error alarm and fault self-diagnosis, Equipped with a communication interface, easy to connect, network, can be the packaging process at all times monitored and networked management. | |

| Scope of material:Powders, granular materials. | ||

| Scope of application:Chemical, pharmaceutical, feed, fertilizer, mineral powder, electric power, coal, metallurgy, cement, biological engineering, etc.. | ||

| Paramete | ||

| Capacity | 160-300bag/h | |

| Accuracy | ≤±0.2% | |

| Size | 5-50Kg/bag | |

| Power souce | Customized | |

| Pressure air | 0.6-0.8MPa. 5-10 m3/h | |

| Blowing rat | 500 -2000m3/h | |

| Environment:Temp -10℃-50℃. Humidity<80% | ||

| Accessories | ||

| Place bag | 1. Manual 3. Automaitic | |

| Protection | 1. Explosion-proof 2. No explosion-proof | |

| Dust elimination | 1. Dust elimination 2. No | |

| Material | 1. Steel 2. stainless steel | |

| Palletizzing | Manual Palletizzing, High-low Palletizzing,Robot Palletizzing | |

| Sew | Automatic 2.Manual | |

Work process

a, Bagging, bag press cylinder press bag, bag inflation airbag inflation

d, At the end of loading, the bag press cylinder is raised to remove the packaging bag

b, Fast feeding process

c, slow feeding process

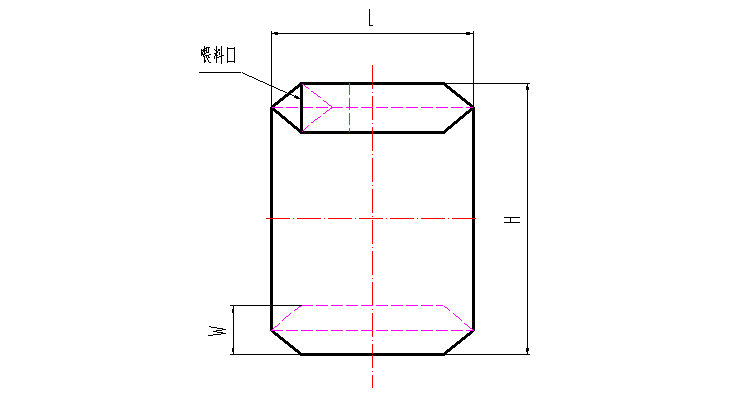

The packaging bag is in the form of a valve pocket.

Users need to choose packaging bags of different specifications according to different packaging weights and different material bulk densities. It is not allowed to choose too large or too small packaging bags at will.

The outline of the packaging bag is as follows.

Receiving agency

When the packaging machine is working, first put the packaging bag on the feeding nozzle, toggle the bag clamping switch, the piston of the bag press cylinder goes down, and the packaging bag is pressed on the feeding nozzle with a nylon plug, and then the feeding starts. During the feeding process, as the weight of the material increases, the scale frame will be displaced, so the load cell will also be deformed, and this deformation is linear within a certain range. The displacement signal is converted into an electrical signal by the load cell and sent to the weighing instrument. When the weight of the material reaches a certain value, the weighing instrument gives a signal, and the packaging process automatically turns to slow speed. When the material weight reaches the target value when the packaging process stops automatically.