General YG series hydraulic cylinders

General YG series hydraulic cylinders

Introduction

The YG series hydraulic cylinders could be displaced by the hydraulic cylinder that was designed by Japanese JISB8354-1992 standard. The features of YGA series hydraulic cylinders are simple in structure, the smaller volume than the other same pressure level hydraulic cylinders. Various mounting mode and easy in changed. The piston rod is plated hard chromium. The hard chromium thickness is 0.03^0.05mm each side. It is widely used in metallurgical, mining, engineering, light chemistry, textile machinery etc. Parts highly in standardization and easy in maintenance.

Technical parameter

| Hydraulic cylinder model | YGB, YGB-L, YGC, YGC-L |

| Working pressure | 7, 14 MPa |

| Experiment pressure | 21 MPa |

| The min. start pressure | <0.3 MPa |

| Working temperature | -10°C~+80"C |

| Allowed max. speed | 300mm/$ |

| Efficiency | >90% |

| Transmission medium | General mineral hydraulic oil |

| Cylinder bore | 40, 50, 63 80, 100, 125 140, 150, 160 |

| stroke (mm) | 500 1200 2000 |

The effective pressed areas of hydraulic cylinder

| bore (mm) | 40 | 50 | 63 | 80 | 100 | 125 | 140 | 150 | 160 | ||

| pressed areas (cm2) | /None-rod chamber | 12.5 | 19.6 | 31.1 | 50.2 | 78.5 | 122.7 | 153 | 176.7 | 201.0 | |

| Rod chamber | Btype | 8.6 | 13.4 | 21.2 | 34.3 | 54.8 | 84.3 | 103 | 119.9 | 137.4 | |

| C type | 10 | 15.6 | 25.0 | 40.3 | 62.6 | 99 |

124.8 |

143.6 | 162.6 | ||

| speed ratio | B type | 1.45 | 1.46 | 1.47 | 1.46 | 1.43 | 1.45 | 1.48 | 147 | 1.46 | |

| Ctype | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.24 | 1.22 | 1.23 | 1.23 | ||

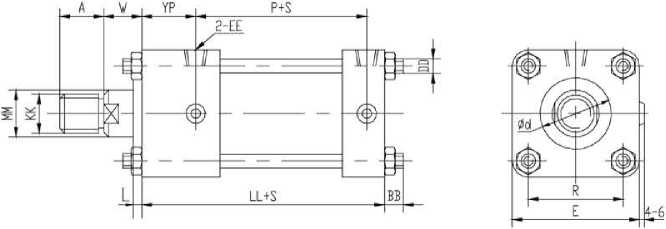

YGB/Standard type

| Bq re /Code f 〜 | 40 | 50 | 63 | 80 | 100 | 125 | 140 | 150 | 160 | ||

| Piston rod size type | B type | A | 30 | 35 | 45 | 60 | 75 | 95 | 110 | 115 | 120 |

| KK | M20X1.5 | M 24X1.5 | M30X1.5 | M39XL5 | M48X1.5 | M64X2 | M72X2 | M76X2 | M80X2 | ||

| MM | 22 | 28 | 35 | 45 | 55 | 70 | 80 | 85 | 90 | ||

| C type | A | 25 | 30 | 35 | 45 | 60 | 75 | 80 | 85 | 95 | |

| KK | M16X1.5 | M20X1.5 | M24X1.5 | M30X1.5 | M39X1.5 | M48X1.5 | M56X2 | M60X2 | M64X2 | ||

| MM | 18 | 22 | 28 | 35 | 45 | 55 | 60 | 65 | 70 | ||

| BB | 11 | 11 | 13 | 16 | 18 | 21 | 22 | 25 | 25 | ||

| DD | M10X1.25 | M10X1.25 | M 12X1.5 | M16X1.5 | M18X1.5 | M22X1.5 | M24X1.5 | M27X1.5 | M27X1.5 | ||

| E | 65 | 75 | 90 | 110 | 135 | 165 | 185 | 196 | 210 | ||

| EE | ZG3/8" | ZG1/2” | ZG1/2H | ZG3/4W | ZG3/4" | ZG1” | ZGT | ZG1H | ZGT | ||

| LL | 141 | 155 | 163 | 1 84 | 192 | 220 | ?30 | 240 | 253 | ||

| P | 90 | 98 | 102 | 108 | 113 | 128 | 135 | 142 | 152 | ||

| R | 45 | 52 | 63 | 80 | 102 | 122 | 138 | 148 | 160 | ||

| W | 30 | 30 | 35 | 35 | 40 | 45 | 50 | 50 | 55 | ||

| YP | 38 | 42 | 46 | 56 | 58 | 67 | 69 | 71 | /4 | ||

| L | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | ||

| d | B type | 40 | 46 | 55 | 65 | 80 | 95 | 105 | 110 | 115 | |

| C type | 36 | 40 | 46 | 55 | 65 | 80 | 85 | 90 | 95 | ||

Write your message here and send it to us